At Dal-Bac Manufacturing, we pride ourselves on being at the forefront of customer needs, providing flame lamination, thermal fusing, and converting processes such as die cutting services. Our focus is not just on manufacturing; it’s about delivering custom solutions that meet our clients’ unique challenges. Here are some recent case studies that showcase how we’ve helped our clients streamline their processes and reduce costs.

Flame Lamination: Elevating Backpack Production

One of our recent projects involved a customer on the East Coast facing difficulties sewing straps for their backpacks. After exploring various solutions, they turned to Dal-Bac for our expertise in design of applications to solve customer needs.

One of our recent projects involved a customer on the East Coast facing difficulties sewing straps for their backpacks. After exploring various solutions, they turned to Dal-Bac for our expertise in design of applications to solve customer needs.

Using durable Cordura fabric, we applied our flame lamination process to create straps that not only met their strength requirements but also saved on adhesive costs. By incorporating foam padding through lamination, we provided a cost-effective solution without compromising on quality. The customer was thrilled with the final product, reinforcing our reputation for technical expertise in custom materials.

Review all of our Case Studies on our website.

Thermal Fusing: Streamlining Costume Production

Another exciting collaboration involved a local costume company that was struggling when using heavy fabrics in their sewing process. They approached Dal-Bac to find a solution that could enhance productivity while maintaining the quality of their appliqués.

Another exciting collaboration involved a local costume company that was struggling when using heavy fabrics in their sewing process. They approached Dal-Bac to find a solution that could enhance productivity while maintaining the quality of their appliqués.

Leveraging our thermal fusing lamination process, we analyzed their specific fabric needs and tailored our approach accordingly. By implementing a combination of materials and adhesives, we were able to significantly improve their sewing process, allowing for greater efficiency and a boost in productivity. The result? A satisfied client and a stronger partnership.

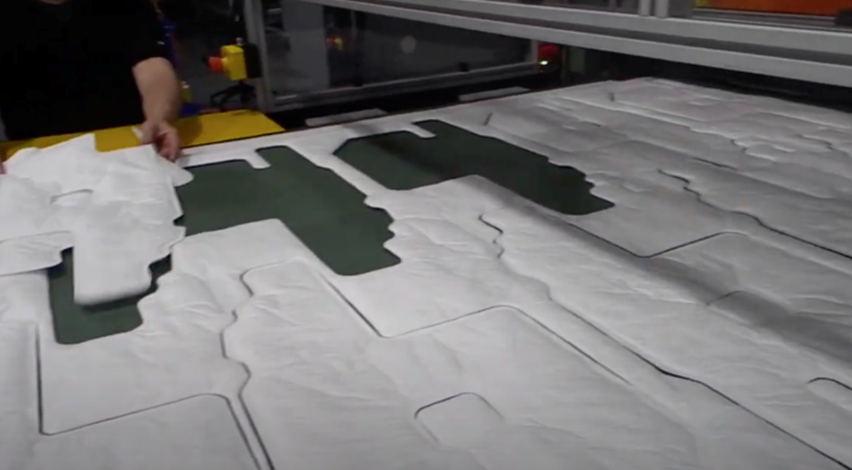

Die Cutting: Redefining Medical Device Applications

In the medical sector, one of our existing customers needed a cost-effective way to convert their 60” wide laminated material into 3” wide straps for intravenous applications. They turned to Dal-Bac for a solution that would help streamline their production process.

In the medical sector, one of our existing customers needed a cost-effective way to convert their 60” wide laminated material into 3” wide straps for intravenous applications. They turned to Dal-Bac for a solution that would help streamline their production process.

Our team utilized steel rule die cutting techniques to efficiently transform the material, ultimately saving the customer time and money by reducing the number of processes involved. The result was an economical solution that enhanced their production capabilities while maintaining the high standards expected in the medical field.

Review all of our Case Studies on our website.

Sourcing Solutions for Orthopedic and Medical Materials

We worked with a global orthopedic and medical supply company that sought to improve the cost and quality of their laminated materials. They had been using Dal-Bac’s services for some time, and they trusted us to find a solution that would enhance their operations.

We worked with a global orthopedic and medical supply company that sought to improve the cost and quality of their laminated materials. They had been using Dal-Bac’s services for some time, and they trusted us to find a solution that would enhance their operations.

With the support of our experienced sourcing team, we successfully addressed their cost concerns while improving material quality. This partnership exemplifies our commitment to not just meet but exceed our clients’ expectations.

At Dal-Bac Manufacturing, we are dedicated to helping our clients overcome their production challenges through innovative solutions. Our flame lamination, thermal fusing, and die cutting services are designed to enhance efficiency, reduce costs, and improve product quality.

Curious to learn more about how we can help your business thrive? Dive into our case studies and discover the transformative impact of our services. Visit our website to explore all our case studies.